Hanyar rage asarar baƙin ƙarfe a cikin ƙirar injiniya

Hanya mafi asali shine sanin dalilin yawan yawan ƙarfe, ko mahimmancin magnetic yana da yawa ko mitar yana da yawa ko kuma jikina na gida ya yi tsanani sosai da sauransu. Tabbas, daidai da hanya na al'ada, a gefe ɗaya, ya zama dole don kusancin gaskiya gwargwadon iko. Dangane da hanyar da aka fi dacewa ita ce ƙara amfani da kyakkyawan zanen silicon, don yanayin aikace-aikace daban-daban suna da ingantacciyar samfurin.

1.

Inganta da'awar magnetic, musamman inganta kaddarorin sinusoidal na filin magnetic. Wannan yana da matukar muhimmanci, ba wai kawai don daidaitawa-mita ba shi da amfani da raga. Mitar mitar ta hanyar yin aikin motsa jiki na motsa jiki yana da mahimmanci. Na taɓa yin motorors biyu tare da ci gaba daban-daban don rage farashi a cikin masana'antar injina, sakamakon, abu mafi mahimmanci shine rashin daidaituwa na filin da iska mai amfani. Saboda aikin yana cikin yanayin girman-sama, asusun da ake amfani da baƙin ƙarfe don babba, don haka asarar baƙin ƙarfe a ƙarƙashin ikon da ke ƙarƙashin ikon da ke ƙarƙashin iko ya wuce sau 2. Hakanan yana tunatar da ku cewa lokacin da kuke yin jujjuyawar motsi na haɓaka, dole ne ku sarrafa dukiyar algorithm don yin.

2.decrease magnetic

Hanya mafi asali shine sanin dalilin yawan yawan ƙarfe, ko mahimmancin magnetic yana da yawa ko mitar yana da yawa ko kuma jikina na gida ya yi tsanani sosai da sauransu. Tabbas, daidai da hanya na al'ada, a gefe ɗaya, ya zama dole don kusancin gaskiya gwargwadon iko. Dangane da hanyar da aka fi dacewa ita ce ƙara amfani da kyakkyawan zanen silicon, don yanayin aikace-aikace daban-daban suna da ingantacciyar samfurin.

3. Optopitimzed da'ircin Magnetic

Inganta da'awar magnetic, musamman inganta kaddarorin sinusoidal na filin magnetic. Wannan yana da matukar muhimmanci, ba wai kawai don daidaitawa-mita ba shi da amfani da raga. Mitar mitar ta hanyar yin aikin motsa jiki na motsa jiki yana da mahimmanci. Na taɓa yin motorors biyu tare da ci gaba daban-daban don rage farashi a cikin masana'antar injina, sakamakon, abu mafi mahimmanci shine rashin daidaituwa na filin da iska mai amfani. Saboda aikin yana cikin yanayin girman-sama, asusun da ake amfani da baƙin ƙarfe don babba, don haka asarar baƙin ƙarfe a ƙarƙashin ikon da ke ƙarƙashin ikon da ke ƙarƙashin iko ya wuce sau 2. Hakanan yana tunatar da ku cewa lokacin da kuke yin jujjuyawar motsi na haɓaka, dole ne ku sarrafa dukiyar algorithm don yin.

4.decrease magnetic

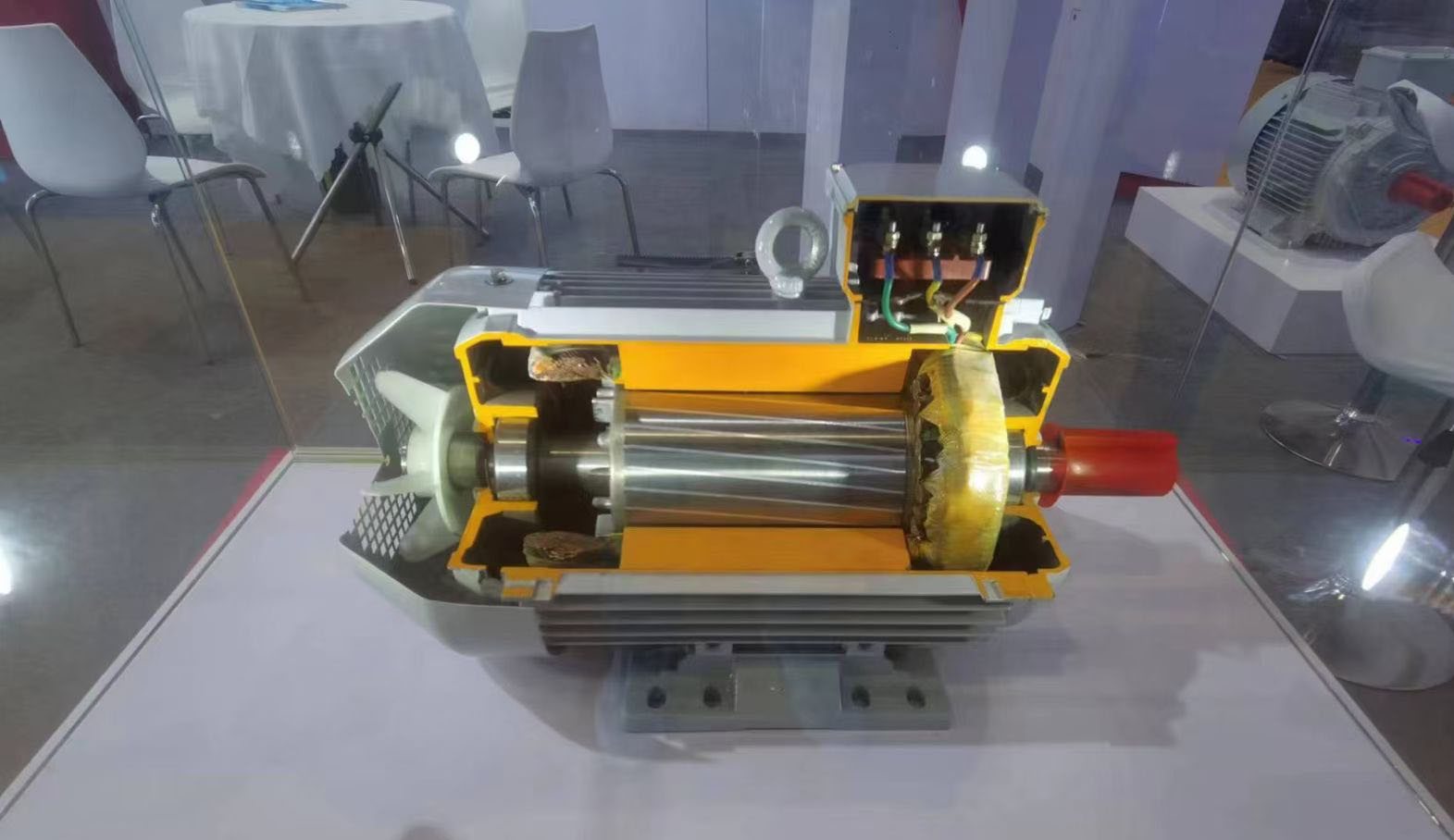

Ariara tsawon baƙin ƙarfe core ko ƙara yawan sihiri na da'irar sihiri don rage yawan ƙwayoyin magnetic don rage yawan ƙwayoyin magnetic, amma yawan baƙin ƙarfe zai ƙaru.

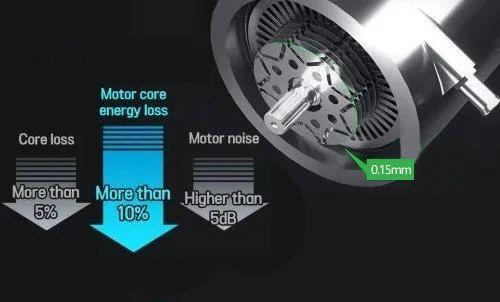

5.redara da kauri daga cikin guntun ƙarfe don rage asarar jawo na yanzu

Idan sanyi-birgima silicon ana amfani da shi a maimakon zafi-birgima takardar silicon, amma kauri daga cikin baƙin ƙarfe core zai kara yawan ma'adinan kwakwalwar baƙin ƙarfe zai iya ƙara yawan ƙwayoyin baƙin ƙarfe da farashin masana'antu.

6.The sanyi

7.Hiighta na samar da katako na baƙin ƙarfe rufin

8.Ka magani da fasahar masana'antu

9.The damuwar baƙin ciki bayan canjin kan ƙarfe zai shafe asarar motar, da kuma shugabanci da kuma puinging m damuwa a kan asarar baƙin ƙarfe a lokacin da silicon karfe takardar silin karfe. Yanke tare da mirgine takardar karfe na silicon da kuma kula da zafi na silicon karfe na iya rage asarar 10% zuwa 20%.

Lokaci: Nuwamba-27-2023